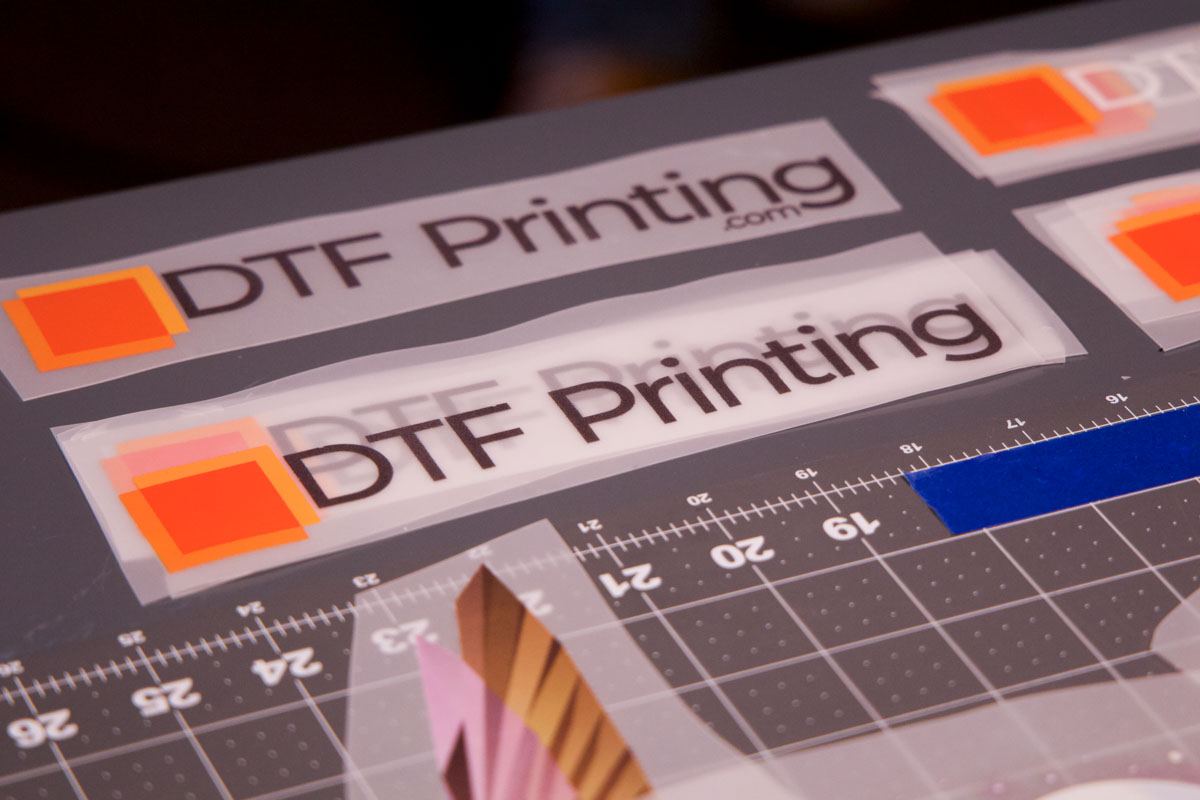

DTF Printing – Understanding the basics of direct-to-film printing for textiles

October 10, 2024 by Adrienne Palmer

Direct-to-film (DTF) printing is a process that involves printing a design onto film using pigment inks and then transferring the design onto a fabric using a heat press. It requires an inkjet digital printer with pigment-based inks, which include CMYK colors and typically a white ink that serves as the base for the design, especially when transferring onto dark fabrics. DTF printing is transforming the apparel decorating industry due to the major benefits it provides to print shops and its customers. The fairly new process allows for faster turnaround times, versatile applications and substrates for various industries, multiple and diverse garment placements, no minimum order quantities, high-quality prints with high color counts, streamlined production, and a low barrier to entry.

DTF printers print onto a film or a transfer. An adhesive powder is then applied to the printed area and the ink bonds with the fabric when heat is applied. The film is then cured to set the powder on the ink. The transfer is then applied to a garment or substrate and pressed with a heat press, which bonds the design to the fabric. You then peel the transfer from the fabric and the final product is ready to wear or use.

DTF vs. DTG vs Sublimation vs Screen Printing

When comparing DTF to other printing methods, each has its own strengths and drawbacks. Here’s a breakdown of some key points:

DTF: DTF offers versatility in terms of the fabrics it can adhere to. It can be applied to a wide range of materials and colors. However, if not executed properly, DTF prints can have a heavy plastic feel, so careful design and execution are crucial.

DTG: DTG printing is ideal for cotton fabrics but may have limitations when it comes to other fabric types. It offers the ability to print full-color designs, but it may not be as versatile as DTF when it comes to fabric options.

Sublimation: Sublimation printing yields excellent results, but it’s primarily suitable for white polyester fabric. It may not work well on other types of fabric or darker colors.

Screen Printing: Screen printing provides a wide variety of inks for different fabric types, but achieving full-color designs can be challenging. Additionally, screen printing requires minimum order quantities and involves preparation processes.

Considering these factors, if your intention is to print exclusively on white or very light-colored polyester tees, sublimation may be the superior choice. However, if you desire the ability to print on various fabric types and colors, DTF printing offers greater versatility. It’s essential to weigh these considerations and choose the method that best aligns with your specific needs and preferences.

When purchasing a DTF printer, you need to consider many factors: your environment and workflow, the quality of equipment and products you purchase, staff training, finding the right vendor who will support you, continuous education, and overall cost. You need to be prepared for maintenance and tech issues and will most likely need to invest in new technology every few years as it advances. Once the printer is in its new environment, you need to spend ample time testing the quality of prints.

If that doesn’t work for your business model, you can outsource transfers and heat-press in-house. When outsourcing, you’re not purchasing a printer, so your overhead cost is lower and training current or future employees is simplified, but you’re relying on a supplier for speed and quality of transfers. If you’re outsourcing everything, you need to find a reliable vendor because this option offers zero control over the process, quality of prints, and turnaround time.

When searching for a vendor, consider a company

- With a history of quality product and service

- That has certified equipment, software, etc

- That will set up equipment for you and train your staff

- Has available staff to support maintenance issues (in-person or virtually)

Offering DTF printing is some capacity, whether you bring everything in-house, outsource transfers, or outsource the entire process, gives you the opportunity to continue saying “yes” to your customers.

Tell us what you think!

Read more articles

We’d love to know how you address issues with color

In order to design better color solutions for you, we’d appreciate your input to the following questions. Thanks!

3 Reasons Why You Should Have a Spectrophotometer

This article was previously published on aldertech.com If you’re a designer, printer, or photographer, you’ve probably heard of…

The Most Important Checkbox in your RIP Color Management Settings

If you’re serious about color accuracy in your printshop, you’ve likely explored output profiles for your large format printers….