DTF Printing: Did I trigger a time machine somewhere?

November 7, 2024 by Marco Roos

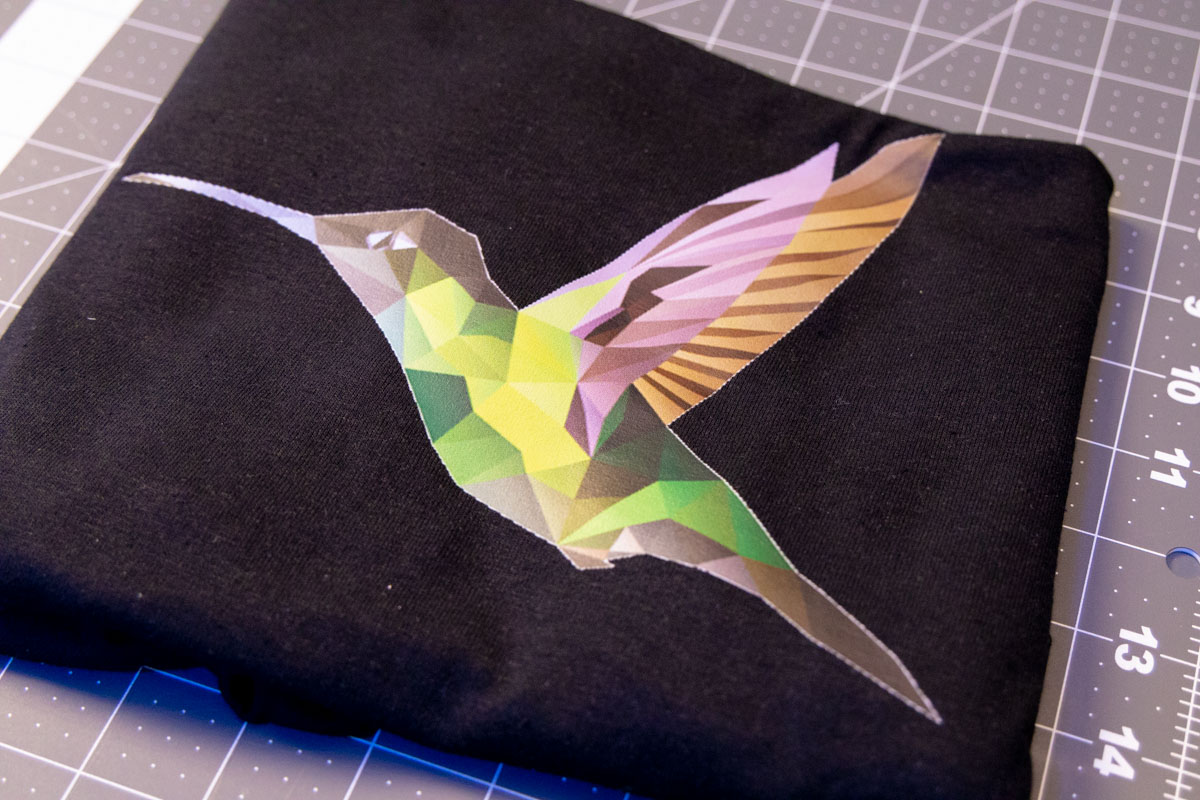

DTF printing has truly stormed the industry, revolutionizing the world of transfers. This shake-up, spearheaded by a surge of innovation from China, has sent Western manufacturers scrambling to keep up. In short, DTF is changing the game—not just in t-shirt transfers but in so many other applications as well. It’s refreshing to see the tables turn as Chinese manufacturers take significant market share with this tech. And guess what? There’s even more to come.

After working hands-on with several DTF print companies across the USA recently, I felt like I was rewinding the clock back 21 years to my early days at Color Concepts (though the mirror tells a different story!) The challenges are all too familiar: printer and ink issues, supply chain headaches, inconsistent color quality, workflow hurdles, file prep confusion… and let’s not forget the ambitious entrepreneurs burning the midnight oil to figure out the optimal mix of humidity, powders, inks, films, and printer settings.

Seeing all this firsthand has been eye-opening. These shops are up against real technical challenges, but there are already solid solutions for many of them. The good news? These solutions are often adaptations from other parts of the printing world, ready to be adopted by this up-and-coming sector.

There’s enough here to fill a book, but I’ll keep it short and focus on some key technical points—file properties, workflow considerations, and, of course, color management. Here’s a look:

1. The Reign of PNG Files

Most DTF print files are in PNG format, which is quite different from the PDF-heavy standards we’re used to in large-format printing and beyond. There has been a ton of standardization work done in the industry, which resulted in PDF/X standards for different printing processes and applications. This has resulted in an entire PDF/X ecosystem with standards, preflighting, and automation capabilities via JDF/XML workflows, creating serious efficiency and profitability for print shops.

But in DTF, it’s still PNG. Why? Many DTF businesses operate through webshops with “gangsheet makers” (similar to “nests” in large format), the majority of which output to PNG. These webshops receive customer uploads of all kinds (PDF, AI, SVG, JPG, and PNG) and nest them onto a sheet, with pricing based on sheet size. Most DTF printers in the U.S. charge by the square inch.

Most shops operate at a maximum print width of 24”, so even in PNG the file sizes are manageable for now. But vector files, which could stay scalable without rasterizing, offer huge advantages in resolution, white ink generation, and cutting. Unfortunately, few DTF printers have grasped the benefits yet, echoing the early years of large-format printing. Development and education in this area are overdue.

2. Image Resolution Blocks Automation

For shops handling hundreds of DTF jobs daily, automation is a necessary step for continued growth. However, the pervasive use of low resolution print files that goes hand-in-hand with allowing customers to upload PNGs and JPEGs is a serious automation blocker. Because each job needs white ink, sometimes cutting, and order bundling, a proper preflight of the files could help a lot in streamlining the printing process afterwards. For example, while reliably generating white ink is something that can be automated, even with low resolution files, reliably adjusting the bleed settings cannot. Low-res uploads result in half-transparent pixels, which makes the white ink layer look very messy and colors on top even worse.

Vector files provide far better control over white ink generation and detail quality. But some shop owners worry that stricter upload requirements might drive customers away—a concern we heard often 25 years ago! This sector needs educational initiatives alongside smarter gangsheet builders or RIP software with cloud nesting technology like PrintFactory. These tools could fix many current issues.

3. Color Management Challenges

DTF printers are highly sensitive to changes in humidity and temperature. One of the complicating factors is that the creation of a transfer is a wild process, compared to what we are used to in large format printing. The artwork is printed mirrored on a transparent film, after which white ink is immediately printed on top after the full color printing has concluded. The wet print then disappears in a powder unit that sprinkles the glue powder on the white ink. After that the film disappears in an oven to melt the glue and cure the inks. This is the final transfer that can be applied to textiles. For profiling and calibrations we have been transferring the targets onto paper, for easier measurements. Due to the many steps in the process, recalibration is required quite frequently. Tests have shown that a daily calibration is necessary to ensure accurate color reproduction.

And here’s the kicker: most DTF printers have minimal understanding of calibration, profiles, and settings, nor do they have the necessary equipment. The software they use often lacks simple, effective calibration tools. With PrintFactory’s Device-link recalibration and Barbieri’s Spectro Swing qb, any print shop can achieve impressive results without any specialized knowledge and very minimal (remote) training.

A lot of the design files are made in RGB, but many companies convert all those files to CMYK in Photoshop first, even if they are vector files. Designs that are supposed to go on a t-shirt are supposed to attract the attention of people, and converting all colors to a small (or unknown) CMYK gamut is probably not the best for the quality of the design. Keep in mind that a lot of the canned printer profiles that are shipped with a lot of the imported printers are poor to very poor quality.

There is a lot to gain in this field! It will lead to ink savings, will reduce waste and will give more consistent output. With the right software and tools, this is much easier to achieve than most think.

4. Automation: The Next Frontier

In my view, workflow automation is the next big leap for DTF printing. By streamlining operations, automation reduces dependence on experts and makes businesses scalable. With PrintFactory’s automation tools and workflow builder, even a simple webshop integration can cut prepress and job prep time by over 80%—a game-changer for shops that want control over productivity and profit, and don't want to rely on expensive experts who bill by the hour to solve their challenges.

Automation also simplifies troubleshooting. Many shops have variables they don’t fully understand, leading to endless trial and error. A tight, clean process clears up desks, and clean desks will make clean heads.

Are you interested in learning more about what we can do to help you with your DTF printing business? Leave us a message, or schedule a call with one of our experts here!

Tell us what you think!

Read more articles

We’d love to know how you address issues with color

In order to design better color solutions for you, we’d appreciate your input to the following questions. Thanks!

3 Reasons Why You Should Have a Spectrophotometer

This article was previously published on aldertech.com If you’re a designer, printer, or photographer, you’ve probably heard of…

The Most Important Checkbox in your RIP Color Management Settings

If you’re serious about color accuracy in your printshop, you’ve likely explored output profiles for your large format printers….