Why Printer Maintenance is Important in Color Management

July 27, 2023 by Shelby Sapusek

It was mid-summer in the Midwest. My business partner and I were driving from our home state to an adjoining one. Our mission was to spend a couple of days profiling printers for a new client.

As always, we had gathered some information before we accepted the job. We knew we were going to be working with two printers of the same brand and model purchased about six months apart.

We also knew that the client was having problems matching color quality between the two machines. Their hope and expectation when they bought two machines of the same model was that they would be able to use them for one job without any noticeable color or print quality differences. That wasn’t happening.

On the drive, my business partner and I brainstormed about our approach to dial these two printers into each other. Our goal was to get them gray balanced so that they both were producing consistent, repeatable and predictable color between jobs.

By the time we arrived at the client site, we felt like we had a good plan of attack. But there was one huge problem.

Not-So-Great Conditions

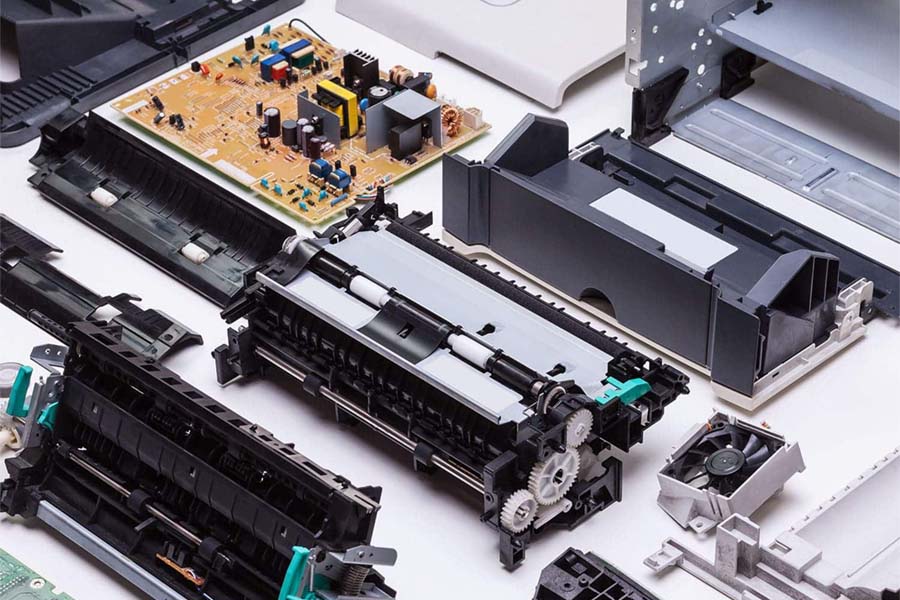

As soon as we saw the two printers, we knew we wouldn’t be making custom ICC profiles for them that day. We could see immediately that the machines had not been properly maintained. We also had concerns about the printing environment.

Upon a quick inspection, the printers were dirty. It appeared that ink had congealed in places. One printer was running and the noise coming from it sounded like a constant head strike was happening.

We also noticed that the room where the two printers were housed was right next to an outside door that was frequently opening and closing. Therefore, the mid-summer humidity was constantly fighting with the air conditioning which was making the air quality unstable.

Until the printing and environmental conditions are in good shape, there is no point in applying any color management strategy. Any adjustments that we might make would be unsustainable because there is no stability – and therefore no hope for repeatability or consistency when it comes to production.

When the conditions are not optimal, you may see a variety of issues in print quality such as blurriness, graininess, ink bleeding or starvation, banding and compressed color gamut.

But there are steps you can take to make your printing environment stable for profiling.

Introducing the Color Management Pyramid

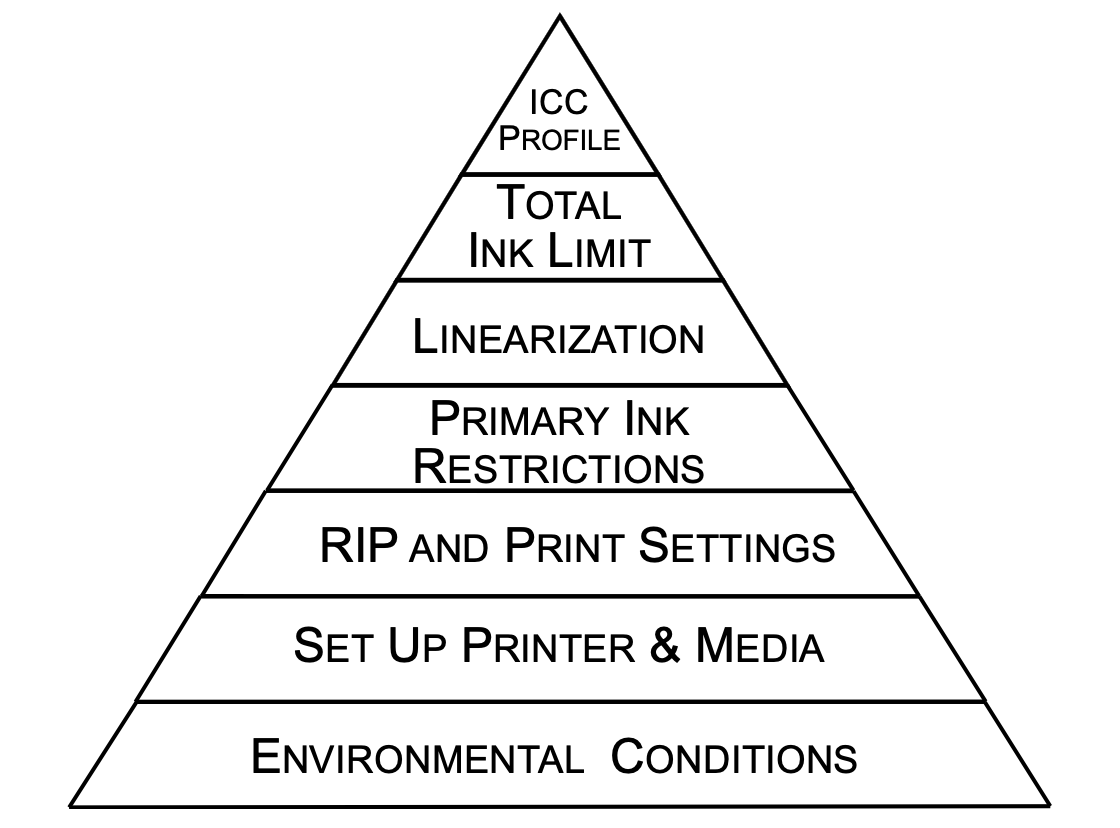

My business partner and I are both certified color management instructors through Printing United Alliance and Idealliance. One of the important pieces of our workshop curriculum is the Color Management Pyramid.

The Color Management Pyramid is a proven methodology that steps a user through a series of steps and checks to produce a custom ICC printer profile. Once that profile is created, the printer should be in gray balance and be able to achieve consistent, repeatable and predictable color.

Stabilizing the System

If you refer to the diagram of the Color Management Pyramid accompanying this article, you will see that it is divided up into seven sections. To use the pyramid, users start at the bottom or base and work their way up to the top where the custom ICC profile is created.

The first three sections at the base are (in order from the bottom):

- Environmental Conditions

- Setting Up The Printer & Media

- RIP and Print Settings

In our workshops, we call these first three steps ‘Stabilizing the System.” These steps are put in place to ensure the printer and the printing environment are optimal for producing good print and color quality.

These two factors go hand-in-hand. The printer needs to be in good shape and well-maintained; but it also needs to be in a climate-controlled and technologically sound printing environment to perform to its best ability.

Controlling the Environment

The word “environment” in this case refers to both climate-related elements and the electrical capacity for the printer(s).

On the climate side, the main considerations are temperature and humidity. The optimum conditions are about 68 degrees Fahrenheit (+/- 10 degrees) and a relative humidity of 30-50% (+/- 10%). Also, relative humidity should be non-condensing in the environment.

As for electrical, the main concern is clean power. Printers need the correct amps and grounded power. When power isn’t clean, the environment can be contaminated by dust, dirt and/or static electricity.

Setting Up The Printer and Media

The second step on the Color Management Pyramid is adjusting the printer and media settings.

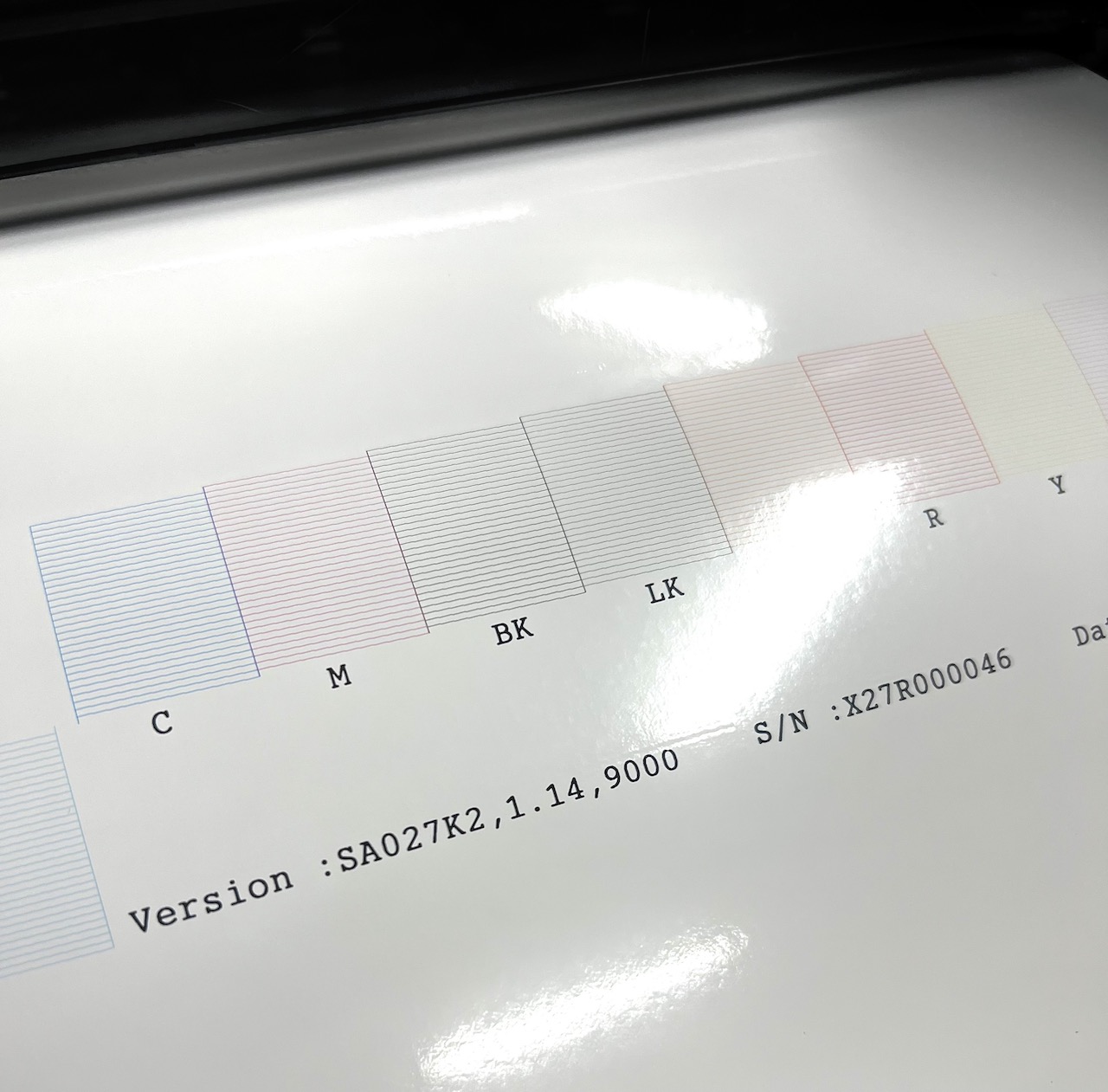

The easiest and maybe the most important check you can make on your printer is a nozzle check. This test forces your printer to create a test print that will indicate whether the ink delivery system is producing the correct amount of ink.

You should also consult your printer’s manual for the correct settings for head alignment, media feed and heat settings if applicable.

Managing the RIP and Print Settings

Like the previous step, your owner’s manual will come in handy to manage the RIP and print settings as well. Every printer has a “sweet spot” that allows it to print to the best of its ability.

Some of the settings to take into consideration are:

- Halftone/Dither Settings

- Resolution

- Pass Count

- Overprint/Second strike

- Variable Dot Setting

- Light Ink Transitions

Now You’re Ready For Color Management

Before you can implement a color management strategy and create a custom profile for your printer, you have to ensure that both your printer and its environment are maintained to optimal conditions.

To do that, you need to stabilize the system. Once you’ve done that, you should be able to achieve gray balance and repeatable, predictable and consistent color across all of your print jobs.

Read more articles

The Most Important Checkbox in your RIP Color Management Settings

If you’re serious about color accuracy in your printshop, you’ve likely explored output profiles for your large format printers….

The Future of Large-Format Printing: AI, Sustainability, and Remote Innovation

This article was previously published on printvergence.com At HP we are already looking to the year ahead and all…

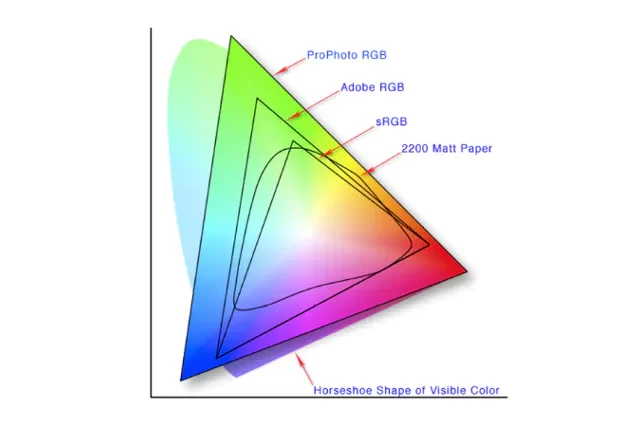

What are the complications of ICC RGB profiles?

As content creators, whether you’re a photographer, graphic designer, or digital artist, understanding the role of ICC RGB colour...