HP Latex Certification

The HP Latex Certification program, developed by ColorBase in partnership with HP, ensures your print materials are optimized for quality and reliability by identifying the perfect printer settings—eliminating trial and error.

This certification not only boosts your product’s visibility through HP’s global platforms but also simplifies customer support and allows you to benchmark performance against competitors.

Certify your material to generate new opportunities and higher sales

Eliminate trial and error for your customers

Finding the correct settings for printer materials is not only time consuming, difficult and expensive, it also decreases your customers' productivity and the overall solution you are able to provide to them. The HP Latex Certification truly makes your material 'plug-and-print'.

Exponentially increase your material's exposure

HP provides a powerful marketing channel to expose your products to your customers. Each HP Latex certification is part of an advanced cloud software solution that will list your certified products onto the front panel of their printers, HP PrintOS, and the HP Media Solutions Locator, which is visited by tens of thousands of HP customers around the world.

Simplify support and complaint handling

Support and complaint handling is much easier with a clear understanding of the capacity of your material. Certifications instantly boost the confidence of your sales teams and distribution channel, as they guarantee quality, reliability, and predictable results.

HP Latex Certifications come in two different flavors, depending on your material

Roll to Roll

Rigid

For materials such as textiles, wall covering, adhesive foils, banners - anything that comes on a roll.

For materials such as such as foam boards, solid plastics, ACP , PVC foam - anything that is rigid.

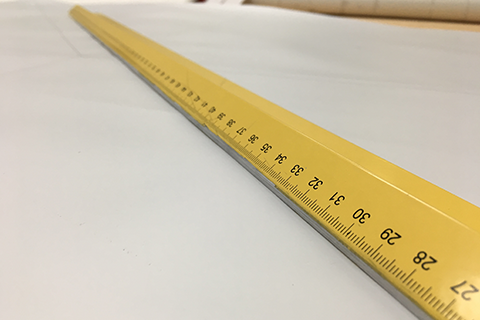

Roll to Roll Materials Certifications

Applicable Printer Series

HP Latex 300 Series

HP Latex 500 Series

HP Latex 630 Series

HP Latex 700/800 Series

HP Latex 1500 Series

HP Latex 3000 Series

HP Latex R-Series

The Certification Process

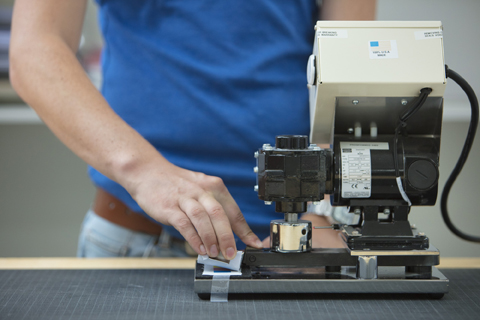

1. Optical print quality check for coalescence, deformation, grain, banding, etc.

We test each materials for obvious visual defects by printing carefully designed test files, designed to expose weaknesses in coating or surface materials. We are checking for issues like: banding, deformation, bleeding, coalescence, and grain. By adjusting the printer settings and finding the right parameters within the bandwidths specified for the respective material, we will try to solve the visual defects.

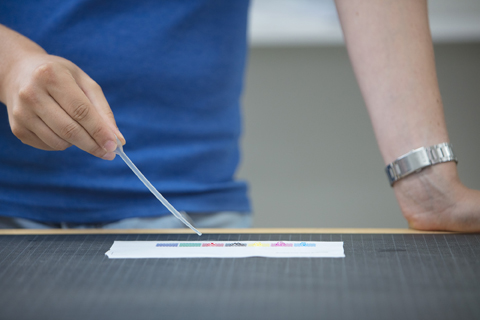

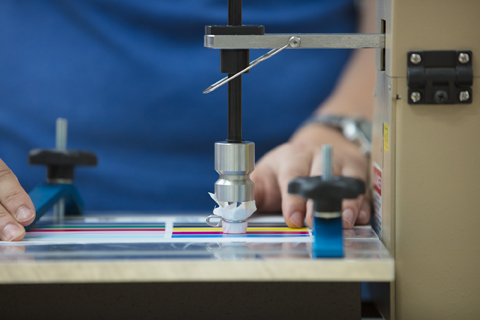

2. Minimum color gamut required for certification

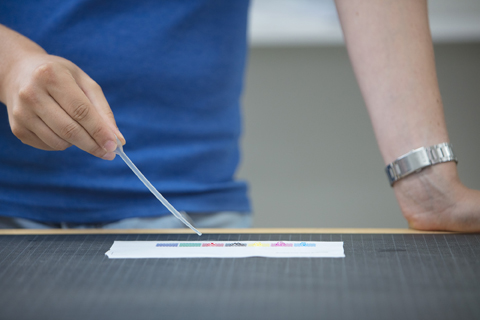

Each material category has predefined color gamut requirements. In other words: we expect a certain color range and quality for each material category. By creating an ICC profile and measuring the gamut volume of these profiles, we are able to determine whether the material capabilities fall within the required bandwidth.

3. Ink migration

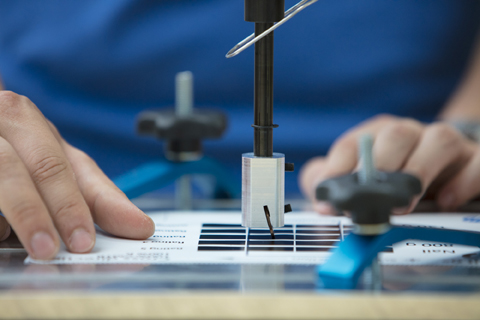

4. Shrinkage

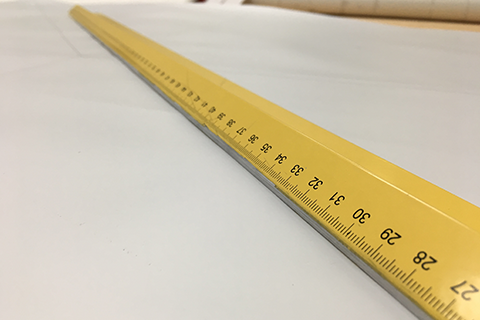

Latex ink requires curing, which has the potential to cause material to dimensionally shrink during the printing process. By printing specially designed test files and measuring the physical print after it has been fully cured, we make sure your material falls within the tolerances set by HP.

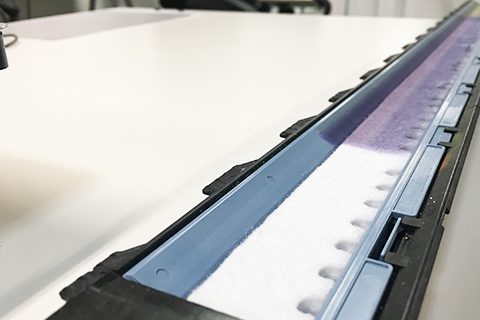

5. Wrinkles

Transporting materials through an inkjet printer must be precise and flawless. Having too much pressure, not enough or too much vacuum power, or too much heat might cause wrinkling of the material during the printing process. By adjusting the printer parameters, we make sure that wrinkling is entirely eliminated, ensuring perfect image quality without any hassle for the printer operator.

6. Washability

7. Water fastness

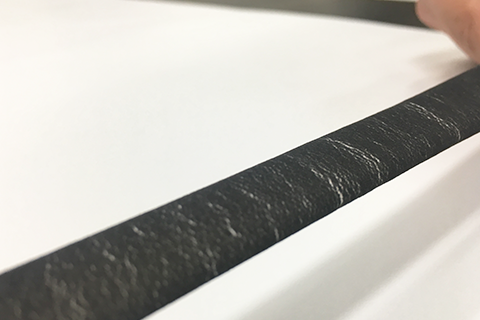

8. Ink cracking under tension

9. Ink adhesion

10. Cross cut ink peel-off

11. Wet / dry rub

12. Scratchability

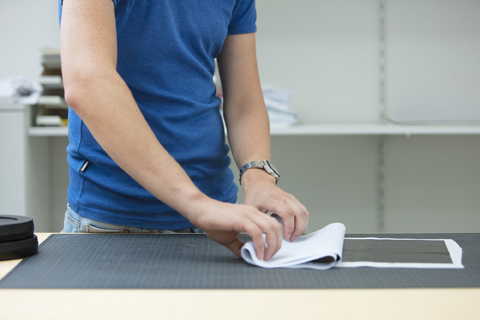

13. Folding / creasing

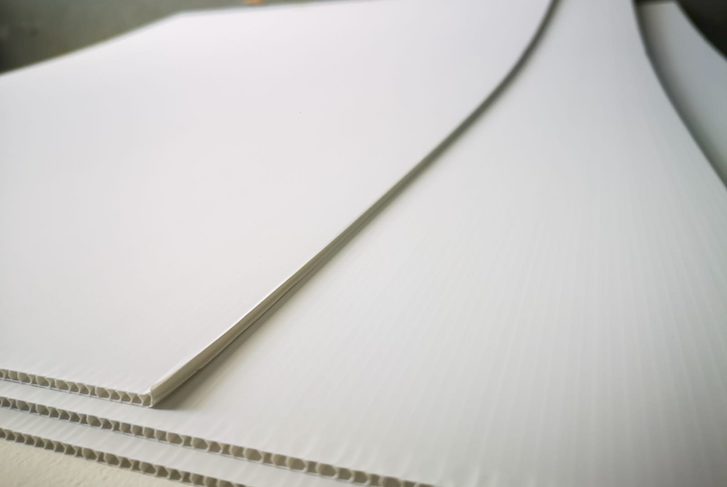

Rigid Materials Certification

Applicable Printer Series

HP Latex R-Series

The Certification Process

1. Optical print quality check for coalescence, deformation, grain, banding, etc.

We test each media for obvious visual defects by printing carefully designed test files, designed to expose weaknesses in coating or surface materials. We are checking for issues like: banding, deformation, bleeding, coalescence, and grain. By adjusting the printer settings and finding the right parameters within the bandwidths specified for the respective media, we will try to solve the visual defects.

2. Minimum color gamut required for certification

Each material category has predefined color gamut requirements. In other words: we expect a certain color range and quality for each material category. By creating an ICC profile and measuring the gamut volume of these profiles, we are able to determine whether the material capabilities fall within the required bandwidth.

3. Shrinkage

Latex ink requires curing, which has the potential to cause media to dimensionally shrink during the printing process. By printing specially designed test files and measuring the physical print after it has been fully cured, we make sure your material falls within the tolerances set by HP.

4. Water fastness

5. Ink cracking under tension

6. Ink adhesion

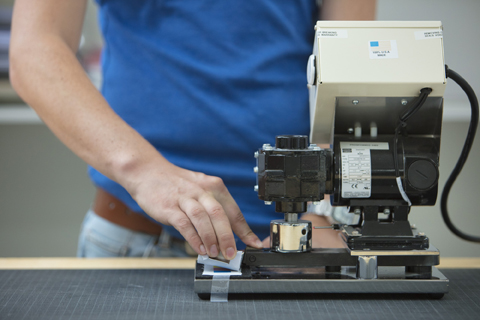

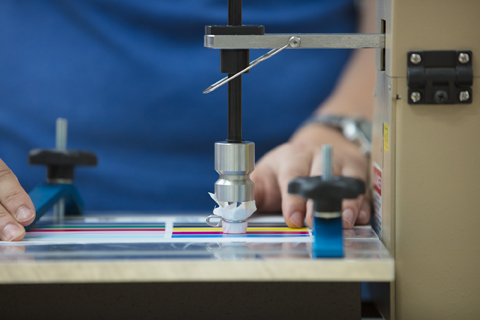

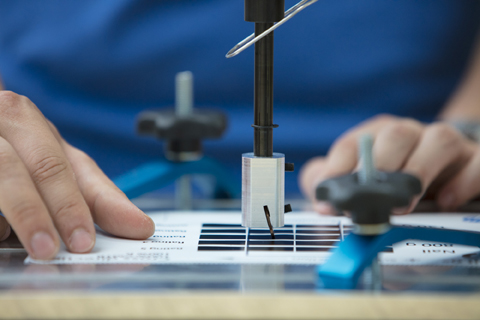

Ink adhesion is a crucial part of any printing process. HP Latex inks have great adhesion properties on compatible materials. This procedure uses industry standard tools to perform the required testing to make sure the materials are compatible with the HP Latex inks and provide the adhesion required for the application the material is designed for.

7. Wet / dry rub

8. Scratchability

9. Stackability

This test will evaluate if your material can be safely stored in piles. We will be checking if there is any ink transfer from your material with the standards set by HP.

Pricing

| Roll To Roll Materials | Price |

|---|---|

| Full Certification - Opaque | € 1,200 |

| Full Certification - Transparent (Multiple Modes), SAV*, Wallpaper, and Backlit Material | € 1,690 |

| Family Check | € 510 |

*Applies to Monomeric, Polymeric and PVC-free Self-Adhesive Vinyls for decorative applications.

| Rigid Materials | Price |

|---|---|

| Full Certification - Opaque | € 1,390 |

| Full Certification - Transparent (Multiple Modes) | € 1,690 |

| Additional Thicknesses R Series - Opaque | € 270 |

| Additional Thicknesses R Series - Colored/Transparent | € 395 |

| Family Check | € 510 |

| MULTIPLE CERTIFICATION DISCOUNTS | |

|---|---|

| Full Certification 4-bundle Discount | -5% |

| Full Certification 6-bundle Discount | -7.5% |