A Guide To Spectrophotometers for Measuring and Verifying Color

October 11, 2023 by Shelby Sapusek

While the concept of color relates to our sense of sight, it usually isn’t perceived accurately with our eyes alone. To help us overcome the limitations of our naked eye, we rely on spectrophotometers for measuring color in the print industry.

Why You Can’t Trust Your Eyes Alone To Perceive Color

First, let’s discuss the limitations of perceiving color with not just our eyes; but also our brains.

One of the problems is simple fatigue. Our eyes get tired as they are used throughout the day. We see color better at 9 a.m. than 9 p.m. Another common problem is stress. When we are feeling stressed, our ability to see clearly is affected. Another physical issue is color blindness; especially in men. Approximately 8 percent or 1 in 12 males will experience some sort of color blindness in life.

If the physical limitations aren’t enough, we also have to battle our brains when it comes to perceiving color. These factors include color memory and color association. Our brain’s recollection of color seen in the past can inhibit how we see color in the present. Additionally, our experiences drive our color recognition as well. For instance, “green grass” and “blue sky” probably means something different to someone living in California versus someone living in New Hampshire.

Bringing Measurement Into The Mix

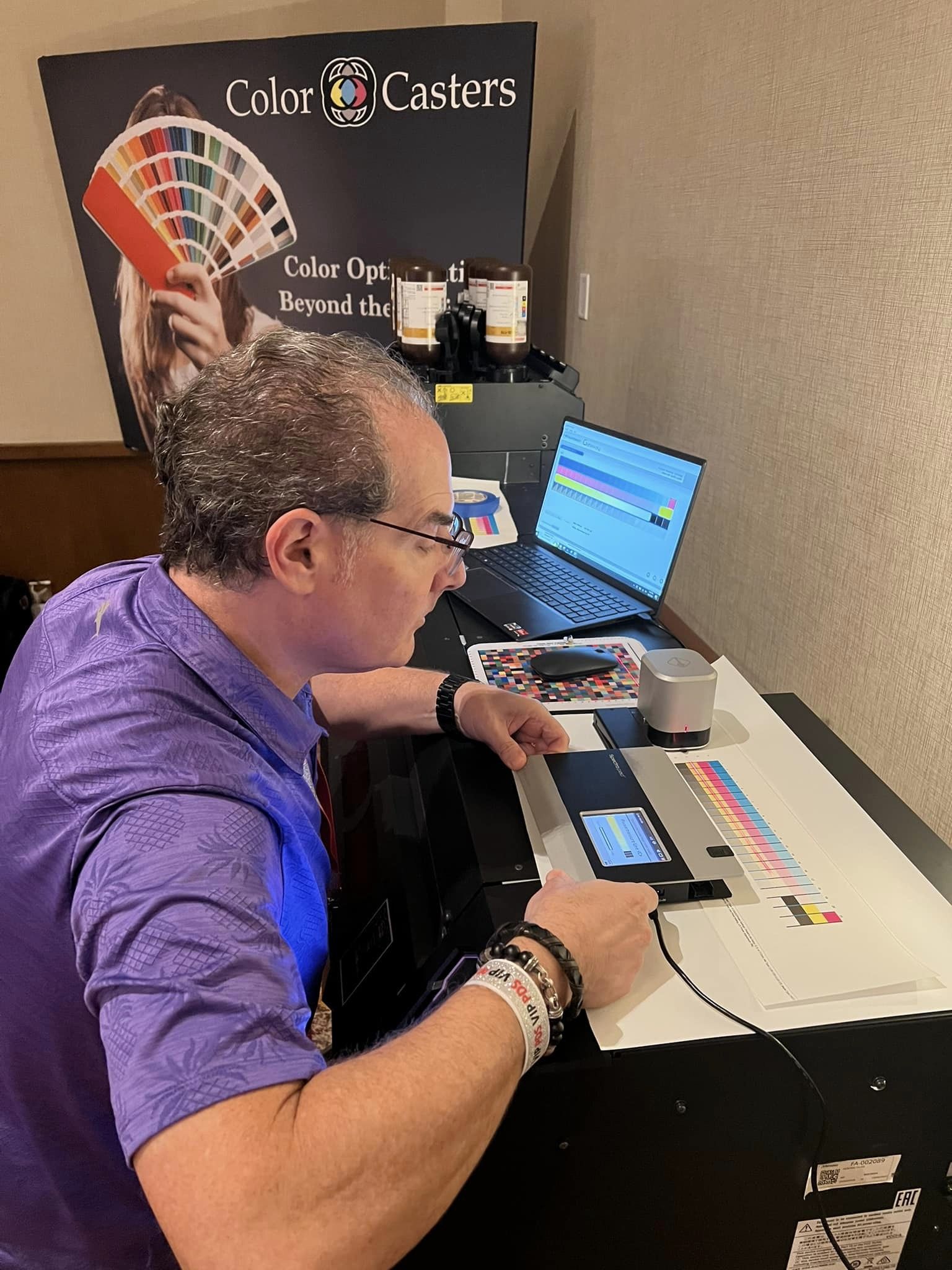

Since we can’t depend solely on our eyes for color verification, we use spectrophotometers to measure test targets or control strips produced from an output device or printer. When the data from these targets is collected into software and compared to a selected industry or in-house standard, we can clearly and accurately assess color quality.

![]()

There is a broad range of measurement devices in the print industry. There are many variables to consider before you choose which one is right for your color management strategy.

Considering The Variables In Spectrophotometers

There are several variables that can drive your spectrophotometer decision.

For instance, what substrate are you wanting to measure and assess? This is where aperture size on the instrument matters.

Smaller apertures are fine for graphics and small patch sizes. But larger apertures let in more light and allow for more repeatable measurements. Larger apertures are needed for textured surfaces such as fabrics. They are also necessary when using a polarization filter and for UV inks.

Lamp type of the spectrophotometer should also be considered. The choice is usually a tungsten bulb versus an LED bulb. Variations in lamp temperature can affect measurement accuracy.

Tungsten bulbs were initially used most often in spectrophotometers because of their low power usage and their consistency once brought up to temperature. Over time however, LED bulbs have become preferable in spectrophotometers.

Exploring Spectrophotometers – From Good To Best

In general, there are three types of spectrophotometers used in the print industry:

- Handhelds

- Handhelds with informational displays

- Automated

That order typically reflects the price point of the various spectrophotometers as well. Handhelds without displays are more inexpensive than those with displays and automated solutions.

Handheld Devices

XRite’s i1 Pro 2 and i1 Pro 3 (Plus) are commonly used handhelds. The i1 Pro 2 uses tungsten bulbs and its aperture is fairly small at 3-3.5 mm. Conversely, the i1 Pro 3 Plus uses LED bulbs and its aperture is 8mm. Both can be used with an iO table for automation but that is much costlier.

Handhelds With Displays

One of the most popular portable spectrophotometers with a display is the

Barbieri Spectropad. It is capable of measuring a large variety of reflective media and is ideal for textile measurements. Its onboard software and easy-to-read display makes it independent from a computer and third party software. It can be used with a direct connection to the printer and provide instant measurement results.

Techkon and Konica Minolta also have handheld spectrophotometers with displays; but their apertures are fairly small and therefore may not be ideal for many substrates or for UV inks.

Automated Solutions

Automation of measurement takes away much of the introduction of human error that can happen with handhelds. It’s also an ideal solution for facilities that take regular measurements and/or create custom ICC profiles.

As mentioned, the Xrite instruments can be paired with a table for automation for an extra cost. But the automated spectrophotometer with perhaps the most accuracy, precision and universal use is the Barbieri Spectro LFP qb.

The LFP qb has all the advantages of the Spectropad but is also suited for reflection and transmission modes. This makes it the ultimate tool for backlit projects. It allows for versatility with a switchable aperture of 2, 6 and 8 mm. The spectral unit is detachable so that it can be used for spot color measurements. While this instrument has one of the highest price points, it is easily the best choice for customers with strict color requirements and for multi-use measurements on a variety of substrates.

The Full Spectrum of Spectros

While there are many options when it comes to spectrophotometers, it comes down to the needs for color assessment in your facility. If you are working with complex substrates and colors and/or will be taking regular measurements while also needing the ability to create custom profiles, a higher-end spectrophotometer solution would probably work best over time.

Read more articles

We’d love to know how you address issues with color

In order to design better color solutions for you, we’d appreciate your input to the following questions. Thanks!

3 Reasons Why You Should Have a Spectrophotometer

This article was previously published on aldertech.com If you’re a designer, printer, or photographer, you’ve probably heard of…

The Most Important Checkbox in your RIP Color Management Settings

If you’re serious about color accuracy in your printshop, you’ve likely explored output profiles for your large format printers….